The IGBT is turned on by applying a positive voltage to the gate (usually V G(on) = +15 V), the typical value of the turn-off voltage is in the range V G(off) = -5...-15 V. At certain values V G(on) / V G (off) the dynamic characteristics of the switch can be set by resistors installed in the gate circuit and limiting its current I G (see Fig. 1, 2).

Rice. 1.

Rice. 2. A, B - limiting the on/off current using resistors R G(on), R G(off), B - voltage V GE and gate current I G

By selecting the R G(on)/R G(off) ratings, you can change the switching time, the level of dynamic losses and switching overvoltages, as well as a number of other parameters, including the composition of the electromagnetic interference spectrum. Thus, selecting the gate drive impedance is one of the most important design steps that requires the utmost attention.

The values of the gate capacitances depend on the collector-emitter voltage V CE IGBT, so they change during its switching. The corresponding graphs of Cies, Coes, Cres versus V CE are given in the technical specifications of the power modules. The impedance of the control circuit, which limits the peak value of the gate current I G at the moments of on and off, determines the recharge time of the input capacitors. Figures 2a and 2b show current flow circuits when using separate resistors on and off lines R G(on) /R G(off), the shape of the gate current I G when a control pulse V GE is applied is shown in Figure 2c.

As the values of R G(on)/R G(off) decrease, the time constant of the recharge circuit decreases, and the switching time t R /t F and the level of dynamic losses E SW decrease accordingly. Despite the positive effect of reducing power dissipation, an increase in the rate of current decay leads to a dangerous increase in the level of switching overvoltages V stray caused by the presence of distributed inductance L S of the DC link power buses: V stray = L S × di/dt.

A visual representation of this effect is given by the diagrams shown in Figure 3.

Rice. 3. Increase in switching overvoltage V stray with increasing di/dt

The shaded area of the graphs, which is the product of the collector current I C and the voltage V CE during the turn-off time, represents the loss energy E off .

If the design of the DC bus is unsuccessful and the value of L S is large, the voltage surge V stray can damage the power switch. The process becomes especially dangerous in the IGBT shutdown mode during a short circuit (short circuit), when the di/dt value is maximum. The V stray level can be reduced by selecting a larger value for the R Goff resistor (15 ohms instead of 10 ohms as shown in the figure). That is why some IGBT drivers (for example, SKYPER 32PRO) implement a soft shutdown mode for SSDs (Soft Shut Down), in which the IGBT is locked through a separate resistor R G (off) of a large value. The natural price for this is an increase in energy losses, therefore, when using modern types of IGBTs and the correct DC bus topology, the use of SSD mode is not recommended.

It should also be noted that increasing switching speeds, leading to an increase in di/dt and dv/dt, also increases the level of electromagnetic interference (EMI) emitted by the converter. Table 1 shows how changing the value of the gate resistor affects the basic dynamic characteristics of the IGBT.

Table 1. Effect of gate resistor on IGBT dynamic properties

| Dynamic characteristics | RG- | RG¯ |

|---|---|---|

| Switching time, t on | ← | ↓ |

| Switch-off time, t off | ← | ↓ |

| Turn-on energy, E on | ← | ↓ |

| Switch-off energy, E off | ← | ↓ |

| Peak inrush current (IGBT) | ↓ | ← |

| Peak turn-off current (diode) | ↓ | ← |

| Rate of voltage change, dv/dt | ↓ | ← |

| Rate of change of current, di/dt | ↓ | ← |

| Switching overvoltage level, V stray | ↓ | ← |

| Electromagnetic interference (EMI) level | ↓ | ← |

SEMIKRON recently launched the fourth generation of modules based on IGBT Trench 4 crystals and fast CAL 4 diodes. One of the main advantages of the new modules is the rate of change of current di/dt reduced by almost 30% with a lower (about 20%) loss energy value. Thanks to this, the use of new keys allows not only to increase conversion efficiency, but also to improve electromagnetic compatibility and reduce the risk of breakdown in emergency situations.

The dynamic characteristics of a boxed IGBT diode also depend on the value of the gate resistor and largely determine its minimum value. The turn-on speed of the transistor should not exceed the reverse recovery speed of the diode: a decrease in the value of R G and a corresponding increase in diC/dt leads not only to an increase in the overvoltage level when the IGBT is turned off, but also creates dynamic stress for the diode.

In its modules, SEMIKRON uses fast diodes produced using its own CAL (Controlled Axial Lifetime) technology, which allows you to change the lifetime of the carriers. Their main difference is the smooth dirr/dt reverse recovery characteristic and the dynamic characteristics optimally matched to the IGBT. This helps reduce the level of dynamic losses and EMI, as well as reduce the magnitude of overvoltages during shutdown.

Gate Resistor Selection

As a rule, the output stage of the drivers is built according to a push-pull circuit with a divided output, as shown in Figure 1. The inputs of both MOSFET transistors are controlled by one logical signal: when it is high, the N-channel switch is opened, and when the level is low, the P-channel switch is opened. Using a split output allows you to generate an asymmetric control voltage V GE and select the values of resistors R G independently for on and off modes.

Optimizing the gate control circuit involves choosing R G(on) / R G(off) ratings (at a given V GE value) that ensure a minimum level of dynamic losses, the absence of dangerous oscillations during switching, a low reverse recovery current of the boxer diode, and a low level of switching overvoltages. The search for the optimum is complicated by the fact that some of the specified parameters are in conflict with each other (see Table 1).

Typically, a smaller gate resistor is required to drive a larger IGBT and vice versa. At the same time, the value of R G indicated as a reference (R Gref) in the technical specifications does not always provide the best balance of the above properties. The optimal resistor value for most specific applications is in the range R Gref ...2 × R Gref. As a rule, the value of R Gref is also the minimum recommended value, ensuring safe shutdown of the maximum permissible pulse current of the IGBT (ICM). Recall that the safe operating area (OSA or SOA) is normalized for ICM or twice the rated collector current ICM = 2 × I C .

In most practical circuits, it is the resistance 2 × R Gref that provides the necessary balance and the process of optimizing dynamic characteristics begins with it. Reducing the gate resistor value is only possible as long as the increasing current switching speed di/dt does not cause dangerous overvoltages to occur. It should also be remembered that reducing the impedance of the gate drive circuit leads to an increase in the current load on the driver and an increase in power dissipation.

The correct choice of R G during design must be confirmed by tests of the finished structure, including analysis of thermal conditions and measurement of the V stray value under all operating conditions up to a short circuit. This is precisely the methodology used by the SEMIKRON design center in France, which over 35 years has developed more than 12,000 projects for various devices with a capacity ranging from tens of kW to units of MW.

When choosing a gate resistance, it should be taken into account that during the flow of charge/discharge currents, a large amount of power can be dissipated on it. It is recommended to select resistors that have a low temperature coefficient TCR and a range of values not exceeding 1%. In most cases, a good solution is to use a parallel connection of a certain number of SMD resistors (MELF, MINI-MELF). This ensures high resistance to pulse overloads, good heat distribution and insensitivity of the circuit to the failure of one of the resistances.

An error in choosing R G can lead to extremely undesirable consequences, and it is necessary to analyze the influence of the gate control circuit on all operating modes of the converter. For example, increasing the R G rating, which makes it possible to reduce the level of switching emissions, will inevitably lead to an increase in dynamic losses and overheating of the power switch. A possible consequence of using an unreasonably large gate resistor may be the transition of the IGBT to linear mode and the appearance of oscillations in the gate circuit. In turn, as already noted, the result of using too small R G is an increase in voltage surges during switching and an increase in the EMI level.

The designer must be aware that optimizing the gate drive circuit cannot compensate for the negative effects caused by poor DC bus design that does not provide a low value of distributed inductance L S . In this case, the level of switching overvoltages can be dangerous even in nominal operating conditions, therefore minimizing the value of L S is the first and main task of developing a DC link. Only if this problem is solved can we think about optimizing R G and the advisability of using the SSD soft shutdown mode.

Currently, MOSFET and IGBT transistors are mainly used as high- and medium-power power switches. If we consider these transistors as a load for their control circuit, then they are capacitors with a capacity of thousands of picofarads. To open the transistor, this capacity must be charged, and when closing, it must be discharged, and as quickly as possible. This needs to be done not only so that your transistor has time to operate at high frequencies. The higher the gate voltage of the transistor, the lower the channel resistance for MOSFETs or the lower the collector-emitter saturation voltage for IGBT transistors. The threshold voltage for opening transistors is usually 2–4 volts, and the maximum at which the transistor is fully open is 10–15 volts. Therefore, a voltage of 10-15 volts should be applied. But even in this case, the gate capacitance is not charged immediately and for some time the transistor operates in the nonlinear part of its characteristic with a high channel resistance, which leads to a large voltage drop across the transistor and its excessive heating. This is the so-called manifestation of the Miller effect.

In order for the gate capacitance to quickly charge and the transistor to open, it is necessary that your control circuit can provide as much charging current as possible to the transistor. The gate capacitance of the transistor can be found out from the passport data for the product and when calculating, you should take Cvx = Ciss.

For example, let's take the MOSFET transistor IRF740. It has the following characteristics that interest us:

Opening Time (Rise Time - Tr) = 27 (ns)

Closing time (Fall Time - Tf) = 24 (ns)

Input Capacitance - Ciss = 1400 (pF)

We calculate the maximum opening current of the transistor as:

We determine the maximum closing current of the transistor using the same principle:

Since we usually use 12 volts to power the control circuit, we will determine the current-limiting resistor using Ohm’s law.

That is, resistor Rg=20 Ohm, according to the standard E24 series.

Please note that it is not possible to control such a transistor directly from the controller; I will introduce that the maximum voltage that the controller can provide will be within 5 volts, and the maximum current within 50 mA. The controller output will be overloaded, and the transistor will exhibit the Miller effect, and your circuit will fail very quickly, since someone, either the controller or the transistor, will overheat first.

Therefore, it is necessary to choose the right driver.

The driver is a pulse power amplifier and is designed to control power switches. Drivers can be upper and lower keys separately, or combined into one housing into an upper and lower key driver, for example, such as IR2110 or IR2113.

Based on the information presented above, we need to select a driver capable of maintaining the transistor gate current Ig = 622 mA.

Thus, we will use the IR2011 driver capable of supporting a gate current Ig = 1000 mA.

It is also necessary to take into account the maximum load voltage that the switches will switch. In this case it is equal to 200 volts.

The next very important parameter is the locking speed. This eliminates the flow of through currents in the push-pull circuits shown in the figure below, causing losses and overheating.

If you carefully read the beginning of the article, then according to the passport data of the transistor you can see that the closing time should be less than the opening time and, accordingly, the turning-off current should be higher than the opening current If>Ir. It is possible to provide a larger closing current by reducing the resistance Rg, but then the opening current will also increase, this will affect the magnitude of the switching voltage surge when switching off, depending on the rate of current decay di/dt. From this point of view, an increase in switching speed is a largely negative factor that reduces the reliability of the device.

In this case, we will take advantage of the remarkable property of semiconductors to pass current in one direction, and install a diode in the gate circuit that will pass the turn-off current of the transistor If.

Thus, the gate current Ir will flow through resistor R1, and the gate current If will flow through diode VD1, and since the resistance of the p–n junction of the diode is much less than the resistance of resistor R1, then If>Ir. To ensure that the turn-off current does not exceed its value, we connect a resistor in series with the diode, the resistance of which will be determined by neglecting the resistance of the diode in the open state.

Let's take the nearest smaller one from the standard series E24 R2=16 Ohm.

Now let's look at what the name of the upper key driver and lower key driver mean.

It is known that MOSFET and IGBT transistors are controlled by voltage, namely the gate-source voltage (Gate-Source) Ugs.

What are the upper and lower keys? The figure below shows a diagram of a half-bridge. This circuit contains upper and lower keys, VT1 and VT2, respectively. The upper switch VT1 is connected by the drain to the positive supply Vcc, and by the source to the load and must be opened by a voltage applied relative to the source. The lower key, the drain is connected to the load, and the source is connected to the power supply negative (ground), and must be opened by voltage applied relative to the ground.

And if everything is very clear with the lower key, apply 12 volts to it - it opens, apply 0 volts to it - it closes, then for the upper key you need a special circuit that will open it relative to the voltage at the source of the transistor. This scheme is already implemented inside the driver. All we need is to add boost capacitance C2 to the driver, which will be charged by the driver supply voltage, but relative to the source of the transistor, as shown in the figure below. It is with this voltage that the top key will be unlocked.

This circuit is quite workable, but the use of a booster capacitance allows it to operate in narrow ranges. This capacitance is charged when the lower transistor is open and cannot be too large if the circuit must operate at high frequencies, and also cannot be too small when operating at low frequencies. That is, with this design, we cannot keep the upper switch open indefinitely; it will close immediately after capacitor C2 is discharged, but if we use a larger capacitance, it may not have time to recharge by the next period of operation of the transistor.

We have encountered this problem more than once and very often had to experiment with selecting a booster capacitance when changing the switching frequency or the operating algorithm of the circuit. The problem was solved over time and very simply, in the most reliable and “almost” cheap way. While studying the Technical Reference for the DMC1500, we became interested in the purpose of the P8 connector.

Having carefully read the manual and thoroughly understood the circuit of the entire drive, it turned out that this is a connector for connecting a separate, galvanically isolated power supply. We connect the minus of the power supply to the source of the upper switch, and the plus to the input of the Vb driver and the positive leg of the booster capacitance. Thus, the capacitor is constantly charged, making it possible to keep the upper key open for as long as necessary, regardless of the state of the lower key. This addition to the scheme allows you to implement any key switching algorithm.

As a power source for charging the booster capacitance, you can use either a conventional transformer with a rectifier and a filter, or a DC-DC converter.

Published 05/15/2014

The design of the power section usually begins with the selection of keys. The most suitable field-effect transistors for this are MOSFETs. The choice of power transistors is made based on data on the maximum possible current and voltage of the motor supply network.

Selection of power transistors

Transistors must withstand the operating current with some margin. Therefore, field-effect transistors with an operating current of 1.2-2 times the maximum motor current are chosen. The characteristics of field-effect transistors may indicate several current values for different modes. Sometimes they indicate the current that the crystal can withstand Id (Silicon Limited)(it is larger) and the current is limited by the capabilities of the transistor body Id (Package Limited)(it's smaller). For example:

In addition, the current for the pulse mode appears ( Pulsed Drain Current), which is significantly greater (several times) than the maximum possible direct current.

It is necessary to select transistors for direct current, and not pay attention to the parameters indicated for the pulse mode. When selecting a transistor, only the DC current value is taken into account. In this case - 195A.

If it is impossible to select a transistor with the required operating current, several transistors are connected in parallel.

In this case, be sure to use the resistors indicated in the diagram. Their nominal value is units of Ohms, but thanks to them, the transistors connected in parallel open simultaneously. If these resistors are not installed, a situation may arise when one of the transistors opens, but the rest do not yet. During this short time, all the power falls on one transistor and disables it. The determination of the value of these resistors is discussed below. Two transistors connected in parallel can withstand twice the current. 3 – 3 times more. But you should not abuse this and build switches from a large number of small transistors.

The selection of field-effect transistors by voltage is also carried out with a margin of at least 1.3 times. This is done in order to avoid failure of transistors due to voltage surges during switching.

In addition to the above parameters, you should ask about the maximum operating temperature of the transistor and whether it will withstand the required current at this temperature. One of the most important characteristics is the resistance of an open transistor. Its values can reach several milliohms. At first glance, it is very small, but at high currents, significant amounts of heat will be generated on it, which will have to be removed. The power that will heat the transistor in the open state is calculated by the formula:

P=Rds*Id^2

Where:

Rds– open transistor resistance;

Ids– the current that flows through the transistor.

Well, it's a transistor irfp4468pbf If the reference is 2.6 mOhm, then under the hour of transmission of 195 A, 98.865 Watts of heat will be seen. In the case of three-phase bridge circuits, only two keys are open at any given time. So, on two closed transistors you will see the same amount of heat (98.865 W each, overall – 197.73 W). All the stinks do not work for the whole hour, but after a while - in pairs, then the skin pair of keys works for 1/3 of an hour. It is correct to say that the heat on all keys will be 197.73 W of heat, and on the skin of the keys (98.865 / 3 = 32.955 W). This is to ensure continuous cooling of the transistors.

So, if the transistor irfp4468pbf has a resistance of 2.6 mOhm, then at a current of 195 A it will generate 98.865 watts of heat. In the case of a three-phase bridge circuit, only two switches are open at any given time. That is, two open transistors will generate the same amount of heat (98.865 W each, for a total of 197.73 W). But they do not work all the time, but in turn - in pairs, that is, each pair of keys works 1/3 of the time. So it is correct to say that in general, 197.73 W of heat will be generated on all keys, and on each of the keys (98.865 / 3 = 32.955 W). Proper cooling of the transistors must be ensured.

But there is one “but”

We have approximately calculated the heat losses that occur during the period when the keys are fully open. However, we must not forget that keys are characterized by such phenomena as transient processes. It is at the moment of switching, when the switch resistance changes from practically zero to almost infinity and vice versa, that the greatest heat generation occurs, which is significantly greater than the losses that occur with open switches.

It is clear that we can load 0.55 Ohm. The live voltage is 100V. When the switches are open, the output voltage is 100/0.55 = 181 A. The transistor turns off and at the current moment its contact drops to 1 Ohm. In one hour after another the flow rate is 100/(1+0.55)=64.5A Do you remember the formula for calculating heat stress? It turns out that this is a very short hour of heat consumption on the transistor (1+0.55)*(64.5^2) = 6448 W. What is more important when the key is unlocked. If the transistor operates up to 100 ohms, it will consume 99.45 watts. If the transistor grows up to 1 KOhm, the consumption will be 9.98 W. If the transistor grows up to 10 KOhm, the consumption will be 0.99 W.

Let's imagine that we have a load of 0.55 Ohm. Supply voltage 100V. With the switches fully open, we obtain a current of 100 / 0.55 = 181 A. The transistor closes and at some point its resistance reaches 1 Ohm. At this time, a current of 100 / (1 + 0.55) = 64.5A flows through it. Remember the formula by which thermal power is calculated? It turns out that at this very short moment the heat loss on the transistor is (1 + 0.55) * (64.5 ^ 2) = 6448 W. Which is significantly more than with a public key. When the transistor resistance increases to 100 Ohms, the loss will be 99.45 W. When the transistor resistance increases to 1 kOhm, the loss will be 9.98 W. When the transistor resistance increases to 10 kOhm, the loss will be 0.99 W.

If you create a very powerful cooling system, more heat will be generated in the transistor than it can physically remove from itself (see: Maximum Power Dissipation), it will burn.

So, it is not difficult to understand that the faster the keys switch, the less heat loss, and the lower the temperature of the keys.

The switching speed of the switches is affected by: the gate capacitance of the field-effect transistor, the value of the resistor in the gate circuit, and the power of the switch driver. How effectively the keys will work depends on the correct choice of these elements.

Sometimes people believe that they can increase the power of the regulator only by changing the keys to more powerful ones. This is not entirely true. More powerful transistors have a larger gate capacitance, and this increases the opening time of the transistor, which affects their temperature. This rarely happens, but I had a case where simply replacing transistors with more powerful ones increased their temperature due to the fact that their switching time increased. So, more powerful transistors require more powerful drivers.

MOSFET key drivers

What is a key driver and why is it needed? Why do we need drivers at all? You can turn on field-effect transistors as shown in the diagram:

Yes, in this case bipolar transistors act as drivers. This is also acceptable. There are also circuits where transistors with a P-channel are used as the upper switches, and with an N-channel as the lower ones. That is, two types of transistors are used, which is not always convenient. In addition, high power P-channel transistors are almost impossible to find. Typically, this combination of transistors with different channels is used in low-power controllers to simplify the circuit.

It is much more convenient to use transistors of the same type, usually only N-channel ones, but this requires compliance with some requirements for controlling the upper transistors of the bridge. The gate voltage of the transistors must be applied relative to their sources (Source). In the case of the lower switch, no questions arise, its turn (Source) is connected to the ground and we can safely apply voltage to the gate of the lower transistor relative to the ground. In the case of the upper transistor, everything is somewhat more complicated, since the voltage at its source (Source) changes relative to ground.

Will explain. Let's imagine that the upper transistor is open and current flows through it. In this state, a fairly small voltage drops across the transistor and we can say that the voltage at the Source source of the upper transistor is almost equal to the motor supply voltage. By the way, in order to keep the upper transistor open, you need to apply a voltage to its gate, the voltage at its source (Source) is higher, that is, the motor supply voltage is higher.

If the upper transistor is closed and the lower one is open, then at the source (Source) of the upper transistor the voltage reaches almost zero.

The upper switch driver supplies the gate of the field-effect transistor with the required voltage relative to its sources (Source), and ensures the generation of a voltage greater than the motor supply voltage to control the transistor. This, and not only this, is what MOSFET switch drivers do.

Driver selection and variety

The variety of drivers is quite large. We are interested in drivers that have two inputs for the upper and lower keys (upper and lower key drivers). For example: IR2101, IR2010, IR2106, IR21064, IR2181, IR2110, IR2113 etc. You need to pay attention to the parameter Vgs your transistors. Most drivers are designed for Vgs=20V. If Vgs transistors, the output voltage of the drivers is lower, for example Vgs transistor = 5V, then drivers with an output voltage of 20V will damage such transistors.

Most drivers are powered by a voltage of 10-20V and support input signals of various levels -3.3V, 5V, 15V.

There are drivers for three-phase bridge circuits, for example:

IR3230, IRS2334, IRS2334, IR21363, IR21364, IR21365, IR21368, IRS2336, IRS23364D, IRS2336D, IRS26310DJ, IR2130, IR2131, IR2132, IR2133, IR2135, IR 2136, IRS2330, IRS2330D, IRS2332, IRS2332D, IR2233, IR2235, IR2238Q, IRS26302DJ.

Such key drivers may be the most suitable option. In addition, some three-phase drivers have an additional feature to protect the switches from too much current, etc. Quite an interesting series of drivers IRS233x(D). It provides a wide range of protections, including surge protection, short circuit protection, overload protection, bus undervoltage protection, power undervoltage protection, and crossover protection.

One of the most important indicators of drivers is the maximum output current. Typically from 200mA to 4000mA. It may seem that 4 Amps is too much. But the calculator decides everything. As noted above, the speed of switching keys is a very important thing. The more powerful the driver, the less time is spent switching keys. You can roughly calculate the key switching time using the formula:

ton = Qg*(Rh+R+Rg)/U

Where:

Qg– full charge of the gate of the field-effect transistor;

Rh– internal driver resistance. It is calculated as U/Imax, where U is the driver supply voltage, Imax is the maximum output current. Note that the maximum output current may be different for the upper and lower transistor;

R– resistance of the resistor in the gate circuit;

Rg– internal gate resistance of the transistor;

U– driver supply voltage.

For example, if we use a transistor irfp4468pbf and driver IR2101 with a maximum current of 200mA. And in the gate circuit there is a 20 Ohm resistor, then the switching time of the transistor is:

540*(12/0.2 + 20 + 0.8)/12 = 3636 nS

Replacing the driver with IR2010, with a maximum current of 3A, and a resistor in the gate circuit of 2 ohms, we obtain the following switching time:

540*(12/3+2+0.8)/12 = 306 nS

That is, with the new driver, the switching time has been reduced by more than 10 times. So the thermal losses on the transistors will be significantly reduced.

Calculation of resistors in the gate circuit

I have developed the following rule for myself: the resistance of the resistor in the gate circuit of the field-effect transistor must be no less than the internal resistance of the driver, divided by 3. For example, the driver IR2101 Powered by a voltage of 12V, maximum current – 0.25A. Its internal resistance: 12V / 0.25 = 48Ohm. In this case, the resistor in the gate circuit of the field-effect transistor must be greater than 48/3 = 16 Ohm. If the switching time of transistors with the selected resistors is not satisfactory, you should choose a more powerful driver.

I cannot call this technique ideal, but it has been tested in practice. If anyone can clarify this point, I would be grateful.

Sometimes a diode with or without a resistor is added to the gate circuit of a transistor.

Since in many cases power transistors operate with inductive loads, protection diodes must be used. If they are not there, then when the transistor is turned off due to transient processes, an overvoltage will occur on the inductances (motor windings), which in many cases breaks through the transistor and disables it.

Many power transistors already have internal protection diodes and there is no need to use external diodes. But do not forget to check this in the documentation for the transistor.

Dead-Time

Changing the state of the power switches in the controller of a three-phase brushless motor is performed in the following sequence:

- turn off the key that needs to be turned off;

- we wait for some time (Dead-Time) until the transistor closes (we calculated the approximate switching time of the transistor earlier) and the transient processes associated with switching end;

- turn on the key that needs to be turned on.

All upper and lower switch drivers have a delay between output signals to prevent both transistors from opening simultaneously (see:). But this delay is too short. Some upper and lower key drivers have real Dead-Time. But in our case, this will not help at all, because if we remember how the keys are switched (see: ), then we will see that there is never a situation when the keys of one arm change states. So, manage Dead-Time must microcontroller. The only exception can be if you use a special three-phase driver that controls all six keys and has a real Dead-Time.

Current sensors

Traditionally, a shunt is used as a current sensor. Knowing its resistance, measure the voltage across it and calculate the current. But for powerful systems, the use of a shunt is not always technically justified due to too large heat losses on it. Hall effect current sensors have virtually zero resistance, so they do not heat up. In addition, as a rule, the power supply and output signal level of such sensors are in the 5V range, which is very convenient for implementing a regulator on microcontrollers. Currently, the company's current sensors are quite popular Allegro MicroSystems, for example series ACS71X, ACS75X.

In addition to the usual measurement of current level with a microcontroller, it is reasonable to create a hardware protection circuit against exceeding a critical current level. The microcontroller takes some time to measure the current level. In addition, the current is measured periodically after some time. Such delays, as well as possible software errors, can create a situation where a critical current manages to damage the device before the next measurement arrives. The circuit must turn off the power switches when the current exceeds a critical value, regardless of the operation of the microcontroller. To implement such a circuit, a comparator is usually used, the input of which is supplied with a signal from the current sensor and a reference signal. When the permissible current is exceeded, the comparator is triggered. The comparator output is used as a discrete signal in logic circuits; the switches are turned off in an emergency. This implementation has the lowest latency.

The driver is a power amplifier and is intended to directly control the power switch (sometimes keys) of the converter. It must amplify the control signal in terms of power and voltage and, if necessary, provide its potential shift.

When choosing a driver, it is necessary to match its output parameters with the input parameters of a powerful switch (MOSFET transistor, IGBT).

1. MOS transistors and IGBTs are voltage-controlled devices, however, to increase the input voltage to the optimal level (12-15 V), it is necessary to provide an appropriate charge in the gate circuit.

3. To limit the rate of rise of current and reduce dynamic noise, it is necessary to use series resistances in the gate circuit.

Drivers for controlling complex conversion circuits contain a large number of elements, so they are produced in the form of integrated circuits. These microcircuits, in addition to power amplifiers, also contain level conversion circuits, auxiliary logic, delay circuits for forming “dead” time, as well as a number of protections, for example, against overcurrent and short circuit, undervoltage and a number of others. Many companies produce a large functional range: lower switch bridge circuit drivers, upper bridge circuit drivers, upper and lower switch drivers with independent control of each of them, half bridge drivers, which often have only one control input and can be used for a symmetrical control law, drivers to control all transistors in the bridge circuit.

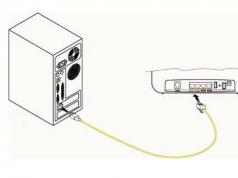

A typical circuit for connecting the driver of the upper and lower keys from International Rectifier IR2110 with the bootstrap power supply principle is shown in Fig. 3.1, a. Both keys are controlled independently. The difference between this driver and others is that the IR2110 has an additional level conversion circuit in both the lower and upper channels, which allows you to separate the power supply of the microcircuit logic from the driver supply voltage by level. It also contains protection against low voltage supply to the driver and high-voltage “floating” source.

Capacitors C D, C C are designed to suppress high-frequency interference in the logic and driver power circuits, respectively. The high-voltage floating source is formed by capacitor C1 and diode VD1 (bootstrap power supply).

The driver outputs are connected to power transistors using gate resistors R G1 and R G2.

Since the driver is built on field elements and the total power spent on control is insignificant, capacitor C1 can be used as a power source for the output stage, recharged from the power supply U PIT through the high-frequency diode VD1. Capacitor C1 and diode VD1 together form a high-voltage “floating” power supply designed to control the upper transistor VT1 of the bridge stand. When the lower transistor VT2 conducts current, the source of the upper transistor VT1 is connected to the common power wire, the diode VD1 opens and the capacitor C1 is charged to voltage U C1 = U PIT - U VD1. On the contrary, when the lower transistor goes into the closed state and the upper transistor VT1 begins to open (Figure 3.1), the diode VD1 is supported by the reverse voltage of the power supply. As a result of this, the driver output stage begins to be powered exclusively by the discharge current of capacitor C1. Thus, capacitor C1 constantly “walks” between the common wire of the circuit and the wire of the power supply (point 1).

When using the IR2110 driver with bootstrap power, special attention should be paid to the selection of elements of the high-voltage “floating” source. Diode VD1 must withstand a high reverse voltage (depending on the power supply of the circuit), a permissible forward current of approximately 1 A, a recovery time t rr = 10-100 ns, i.e. be fast. The literature recommends the SF28 diode (600 V, 2 A, 35 ns), as well as diodes UF 4004...UF 4007, UF 5404...UF 5408, HER 105... HER 108, HER 205...HER 208 and other “ultra - fast” classes .

The driver circuit is designed in such a way that a high logical signal level at any input HIN and LIN corresponds to the same level at its output HO and LO (see Fig. 3.1 b, common-mode driver). The appearance of a high level logic signal at the SD input leads to the blocking of the transistors of the bridge rack.

It is advisable to use this microcircuit to control inverter switches with PWM output voltage regulation. It must be remembered that in the control system it is necessary to provide time delays (“dead” time) in order to prevent through currents when switching bridge rack transistors (VT1, VT2 and VT3,VT4, Fig. 1.1).

Capacity C1 is a bootstrap capacity, the minimum value of which can be calculated using the formula:

Where Q 3– value of the gate charge of a powerful switch (reference value);

I pit– driver consumption current in static mode (reference value, usually I pit≈ I G c t powerful key);

Q 1– cyclic change in driver charge (for 500-600-volt drivers 5 nK);

V p– supply voltage of the driver circuit;

– voltage drop across the bootstrap diode VD1;

T– switching period of powerful keys.

Fig.3.1. Typical circuit diagram for switching on the IR2110 driver (a) and timing diagrams of its signals at the inputs and outputs (b)

V DD – microcircuit logic power supply;

V SS – common point of the logical part of the driver;

HIN, LIN – logical input signals that control the upper and lower transistors, respectively;

SD – logical input to disable the driver;

V CC – driver supply voltage;

COM – negative pole of the power supply V CC;

HO, LO – driver output signals that control the upper and lower transistors, respectively;

V B – supply voltage of the high-voltage “floating” source;

V S is the common point of the negative pole of the high-voltage “floating” source.

The resulting value of the bootstrap capacitance must be increased by 10-15 times (usually C within 0.1-1 μF). This should be a high-frequency capacitance with low leakage current (ideally tantalum).

Resistors RG 1, R G 2 determine the turn-on time of powerful transistors, and diodes VD G 1 and VD G 2, bypassing these resistors, reduce the turn-off time to minimum values. Resistors R1, R2 have a small value (up to 0.5 Ohm) and equalize the spread of ohmic resistance along the common control bus (required if a powerful switch is a parallel connection of less powerful transistors).

When choosing a driver for high-power transistors, you must consider:

1. Law of control of powerful transistors:

For symmetrical law, high and low switch drivers and half bridge drivers are suitable;

Single-ended law requires upper and lower key drivers with independent control of each powerful key. Drivers with transformer galvanic isolation are not suitable for an asymmetrical law.

2. Parameters of a powerful key (I to or I drain).

An approximate approach is usually used:

I out dr max =2 A can control powerful VT with current up to 50 A;

I out dr max =3 A – control a powerful VT with a current of up to 150 A (otherwise the on and off time increases significantly and the power losses for switching increase), i.e. If a high-quality transistor is chosen incorrectly, it loses its main advantages.

3. Accounting for additional functions.

Companies produce drivers with numerous service functions:

Various powerful key protection;

Driver undervoltage protection;

With built-in bootstrap diodes;

With adjustable and non-adjustable delay time for turning on a powerful VT in relation to the moment of turning off the other (combat through currents in the half-bridge);

With or without built-in galvanic isolation. In the latter case, a galvanic isolation microcircuit (most often a high-frequency diode optocoupler) must be connected to the driver input;

In-phase or anti-phase;

Driver power supply (bootstrap power supply or three galvanically isolated power supplies are required).

If several types of drivers are equivalent, preference should be given to those that switch the gate current of powerful transistors using bipolar VTs. If this function is performed by field-effect transistors, then there may be failures in the driver’s operation under certain circumstances (overloads) due to the “latching” trigger effect.

After selecting the type of driver (and its data), measures are necessary to combat through currents in the half-bridge. The standard method is to turn off a powerful key instantly, and turn on a locked one with a delay. For this purpose, diodes VD G 1 and VD G 2 are used, which, when closing VT, bypass the gate resistors, and the shutdown process will be faster than unlocking.

In addition to shunting the gate resistors R G 1 and R G 2 using diodes (VD G 1, VD G 2, Fig. 3.1) to combat through currents in the P-circuit of a powerful cascade, companies produce integrated drivers that are asymmetric in the output switching current VT I other out m ah on on and off I other out m ah off(For example I other out m ah on=2A, I other out m ah off=3A). This sets the asymmetric output resistances of the microcircuit, which are connected in series with gate resistors R G 1 and R G 2.

where all values in the formulas are reference data for a specific driver.

For a symmetrical (current) driver, the following equality is true:

.

.

There are three capacitances in the MOSFET transistor structure: gate-source capacitance (input capacitance), source-drain capacitance (output capacitance), gate-drain capacitance (pass-through For the IGRT transistor, respectively, , . When a voltage of (15-20) V is applied to the gate, it starts the input capacitance will charge exponentially and at a voltage of 8-10 V a current will appear in the transistor... This period of time is given in the form of the turn-on delay parameter (Fig. 3.2) at a certain resistance in the gate circuit

When a drain current appears in the VT structure, the input capacitance will be charged at a different exponential rate, since this process is influenced by the output capacitance, then ultimately the input capacitance will accumulate charge Q (reference value). The output current (voltage reduction at the source-drain electrodes) will mainly depend on the processes in the circuit, without a significant influence of the gate current.

The capacity discharge time is also given in the VT reference parameters in the form of on time.

When the transistor is turned off, the capacitance will first discharge to a value (), then the source current will begin to decrease to 0 (). Thus, the delay for turning on and off VT will depend on the value of the resistor in the gate circuit, and with the use of a driver, the total resistance in the gate circuit will have two components: (with an unbalanced driver and ) - const and an additional gate resistor, which can be changed for adjustments delays Figure 3.2 presents the above arguments in the form of simplified graphs.

Rice. 3.2. Timing diagrams: (a) - when VT is turned on; (b) - when VT is turned off.

The reference data does not provide the parameters of the input and output capacitances of the transistor, but it is known from mathematics that the initial portion of the exponential (up to 0.7) is approximated by a straight line, the angle of inclination of which is directly proportional to RC, which allows estimation calculations in the form of proportions.

So, to prevent the occurrence of through currents, it is necessary to select the total value of resistance in the gate circuit (  , and regulates the charging rate of the gate capacitance VT) to provide a delay in turning on the transistor greater than or equal to the time spent closing VT (see Fig. 3.2).

, and regulates the charging rate of the gate capacitance VT) to provide a delay in turning on the transistor greater than or equal to the time spent closing VT (see Fig. 3.2).

(3.1)

(3.1)

where is the decay time of the drain current (reference value);

– delay time of the beginning of VT switching off relative to the moment the blocking voltage is applied to the gate. With shunt gate diodes (VD G 1, VD G 2, Fig. 3.1), the discharge rate is uniquely determined by the resistance  . Therefore, to determine the following proportion is solved (assuming that it will be shunted by the diode VD G)

. Therefore, to determine the following proportion is solved (assuming that it will be shunted by the diode VD G)

When developing power circuits for static converters, measures to protect power transistors from thermal runaway are paramount. Since MOSFET field-effect transistors do not have secondary breakdown, thermal calculations can be based on the maximum temperature and maximum power dissipation values. The total power released by the transistor in its switching mode is determined from the expression:

where R p is the total power dissipation;

R per - power loss during switching;

R pr - losses on the active resistance of the open transistor channel;

Pynp - control losses in the gate circuit;

Pyr - power loss due to leakage in the closed state.

where L L(op) is the resistance of the transistor in the open state (reference parameter).

Conduction losses P pr are the main component of losses in a field-effect transistor. These losses can be calculated by knowing the effective (rms) value of the drain current:

Power losses caused by leakage current (P^) are negligible (if, of course, the transistor is working), so there is no point in taking them into account at all. In addition, since one of the main advantages of a field-effect transistor is extremely low losses in its control circuit (P control), therefore, the value of control losses can be excluded from the calculations. Taking into account the assumptions made, formula (2.1.7) for calculating total losses takes the following convenient form:

Here it is necessary to make some clarifying digression and remind the reader that the calculation of power dissipation is performed in order to ensure the thermal conditions of power transistors. This calculation will be useful when designing cooling radiators for transistors (for details, you can refer to publications and). A very important parameter, without which it will not be possible to design a cooling element, is the so-called “chip-to-case” thermal resistance R thjc of the transistor. Research has shown that this resistance largely depends on the switching frequency of the transistor, as well as on the duty cycle of control pulses, determined by the ratio of the open state time to the full switching period. In the technical specifications for transistors, the so-called normalized transient thermal impedance junction-to-case characteristics are usually given. As can be seen from Fig. 2.1.11, due to the inertia of thermal processes at high switching frequencies and low duty cycle, the thermal resistance of the “crystal-case” is significantly reduced. In any case, the developer needs to estimate this resistance according to the schedule, so as not to design the radiator for cooling the power elements “by eye.” The reader should be aware that those shown in Fig. 2.1.11 graphs are included in the main set of parameters presented by manufacturing companies for the power element base. If, when choosing an element base, the developer is faced with the fact that these graphs are not in the documentation, it is better not to trust such a manufacturing company and not to use its products in your developments.

Taking into account graphs 2.1.11, the thermal resistance of the “crystal body” is determined by the following formula:

where ZjJJ, D) is the transition coefficient of resistance “crystal body”;

R Q (JC) - thermal resistance “crystal-case” in the mode of large duty cycles of control pulses or at direct current.

In Fig. 2.1.11 there is another curve called single pulse. It is removed for a single (non-repeating) current pulse. This mode of operation is typically used for protection and triggering circuits that operate once. In this case, as a rule, the heat generation is small and the power element does not require a radiator.

But let's return to heat losses. The situation with switching losses is much more complicated. If the load of the field effect transistor is purely

Rice. 2.1.11. Graph of the dependence of the normalized thermal resistance on the frequency and duty cycle of the pulses: a - IRFP250; b - IRJL3103D1; in -FB180SA10

active, switching losses are small and can often be simply ignored. However, active load is a rare case in power converter technology. Much more often, transistors of static converters “work” on loads with a strongly pronounced reactive (inductive-capacitive) component, which is characterized by a mismatch of maximum currents and voltages. In addition, in transistors operating in push-pull circuits (this includes half-bridge, bridge and three-phase circuits), specific reverse recovery losses of opposed diodes occur. We will immediately turn to methods for calculating dynamic losses in push-pull circuits, since it is on their basis that powerful converter technology is built.

In a push-pull circuit, it is necessary to consider the influence of inductance L on the remaining elements of the circuit. It should be remembered that in reality the inductance L is the magnetizing inductance of the primary winding of a high-frequency transformer (if the device being designed is a static converter for powering typical loads), or the inductance of the motor winding (if an adjustable frequency electric drive is being developed).

Let's turn to Fig. 2.1.12 and consider the switching processes occurring in the presented typical circuit. Initially (what

opening of the key element. It is clear that the amplitude of the surges cannot become greater than the supply voltage or ground potential, since the opposed diodes will open and “discharge” the surges to the power source. And yet, if the energy of the oscillatory process is high enough, it may not end by the time the key element is next discovered. Switching when current flows through the reverse diode will lead to a so-called “hard switching” situation, when the power transistor will briefly be in the “through current” mode. To “extinguish” these emissions, an RC circuit with a capacitor and resistor connected in series is connected in parallel to the primary winding of the transformer.

We have just examined the so-called “light” mode of operation of the transistor in push-pull circuits, when control pulses arrive at the gates VT1 and VT2 symmetrically, and at the moment of commutation the currents do not pass through the opposed diodes. It is not difficult to calculate the switching loss power in this case. For each transistor operating in a half-bridge or bridge circuit with a standard transformer load, it can be calculated using the formula

where /^max is the maximum drain current.

There is another case when transistors are forced to operate in a “heavy” switching mode. This case is usually considered in frequency control devices for motors with significant winding inductance. Here, the duration of the open state of the “upper” (VT1) and “lower” (VT2) key elements of the half-bridge and bridge may be unequal: in the extreme case, the opening pulses of one of the power switches disappear altogether. In the case of asymmetry of control pulses, the current in the inductive load does not change its direction, which means that, for example, after turning off the transistor VT2, the current i L (Fig. 2.1.12 c) will flow through its opposed diode. Consequently, turning off transistor VT1 will occur in short-term short circuit mode, since diode VD2 will not be able to instantly restore the locked state. The longer the box diode delays restoring the off state, the more heat will be generated in the transistor. Therefore, to calculate switching losses in “heavy” mode, it is necessary to take into account both the dynamic switching losses of the transistor and the reverse recovery losses of the opposed diodes. The following formula will help you calculate switching losses:

where Q rr is the reverse recovery charge of the boxer diode (reference parameter).

You should also know that the reverse recovery charge of a boxed diode (according to Fig. 2.1.14) slightly depends on the forward current flowing through the diode after turning off the transistor, but is largely determined by the magnitude of the change in the forward current over time at the reverse recovery stage, that is, the magnitude derivative of the current. In practice, this means that slowing down the switching process that causes reverse recovery can reduce the charge, and therefore the energy released. Therefore, in “heavy” switching mode, it is necessary to slow down the process of opening the field-effect transistors. The opening speed can be reduced by limiting the gate current by increasing the gate resistor, as well as bypassing the drain-source junctions of the transistors with RC circuits that limit the switching speed. True, at the same time, switching dynamic switching losses increase.

Rice. 2.1.14. Dependence of the reverse recovery charge of the diode on the speed of the switching process

Quite often in the practice of developing static converters, there are cases when it is necessary to switch a current whose value is higher than the limiting current of a single transistor. And if it turns out to be difficult to choose a more powerful device, you can simply connect several devices in parallel, designed for lower currents. Then the total current will be evenly distributed among the individual transistors. To connect them in parallel, you need to have devices with close threshold voltage values. As a rule, transistors of the same type have very close threshold voltage values, so it is extremely undesirable to choose transistors of different types for parallel operation. Or better yet, take transistors from the same production batch, manufactured under the same conditions.

To ensure uniform heating of the line of transistors, they need to be installed on a common radiator and, if possible, closer to each other. It must also be remembered that through two parallel-connected transistors, you can pass twice the current without reducing the load capacity of single devices, but at the same time, the input capacitance, and therefore the charge of the combined gate, doubles. Accordingly, the control circuit for parallel-connected transistors must be able to provide the specified switching time.

But here too there are some peculiarities, some “tricks”. If you connect the gates of field-effect transistors directly, you can get a very unpleasant “ringing” effect when turned off - influencing each other through the gates, the transistors will randomly open and close, not obeying the control signal. To eliminate “ringing”, it is recommended to put small ferrite tubes on the gate terminals to prevent mutual influence of the gates, as shown in Fig. 2.1.15, a.

This method is very rare today (since the technology for producing ferrite tubes is quite complex). A simpler and more accessible circuit design is shown in Fig. 2.1.15, b,

Rice. 2.1.15. Parallel connection of MOSFET: a - with quenching ferrite tubes; b - with gate resistors

which consists in installing identical resistors with a resistance of tens to hundreds of ohms in the circuits of each gate. The value of gate resistors is usually selected from the ratio:

where Q g is the value of the gate charge for one transistor.

After this, it is necessary to determine the amount of current provided by the transistor gate control device. This current is determined from the condition of the action of voltage U g on parallel connected gate resistors. That is, the value of R g obtained from formula (2.1.13) must be reduced during calculations by as many times as the number of transistors connected in parallel.

Rice. 2.1.16. Option for parallel connection of MOSFET transistors

Transistors VTl...VT4 are installed on a common radiator as close to each other as possible, which ensures their uniform heating. Power buses, which can be made of either printed or solid conductors (for example, copper strip or tinned wire), are connected to the drain and source of all transistors. Gate resistors Rg can be placed above the power busbars. The transistors are secured to the radiator using screws and pressure springs. Sometimes to improve thermal contact between

radiator housings use the following technology: transistors are attached with their heat-removing plates to a common strip of copper (or its alloys), and it, in turn, is screwed to the radiator, previously lubricated at the point of contact with heat-conducting paste. And, of course, it is necessary to ensure electrical insulation of individual groups of transistors in order to avoid short circuits in places where they should not exist according to the electrical circuit.

In Fig. 2.1.17 shows the appearance of a variant of the structural unit of a three-phase controlled bridge, composed of parallel-connected MOSFET transistors, and in Fig. 2.1.18 - electrical diagram for connecting transistors. The radiator has through channels through which it is forced to be blown with air flow.